VPF POLYIMIDE 691008

ADHESIVE MATERIAL FOR EXTREME THERMAL

AND CHEMICAL RESISTANCE IN ELECTRONICS MANUFACTURING

ADHESIVE MATERIAL FOR EXTREME THERMAL

AND CHEMICAL RESISTANCE IN ELECTRONICS MANUFACTURING

VPF POLYIMIDE 691008

ADHESIVE MATERIAL FOR EXTREME THERMAL AND CHEMICAL RESISTANCE IN ELECTRONICS MANUFACTURING

ADHESIVE MATERIAL FOR EXTREME THERMAL AND CHEMICAL RESISTANCE IN ELECTRONICS MANUFACTURING

With VPF Polyimide 691008, VPF offers an self-adhesive material specially developed for PCB marking that meets the highest requirements in electronics manufacturing. The self-adhesive material combines high thermal resistance, very good chemical resistance and excellent printability.

The 50 µm thick polyimide with a white, silk matt coating offers excellent printability and optimum contrast – ideal for barcodes, data matrix codes and variable information. In combination with the high-performance acrylic adhesive 801, the material ensures reliable adhesion even under extreme conditions.

Regardless of the soldering process: The adhesive is designed for high-temperature applications up to 300 °C for short periods and remains securely fixed to the circuit board even after thermal and chemical stress in the solder bath.

VPF Polyimide 691008 is available from 200 m² with a working width of 1,020 mm and is ideal for further processing by label manufacturers.

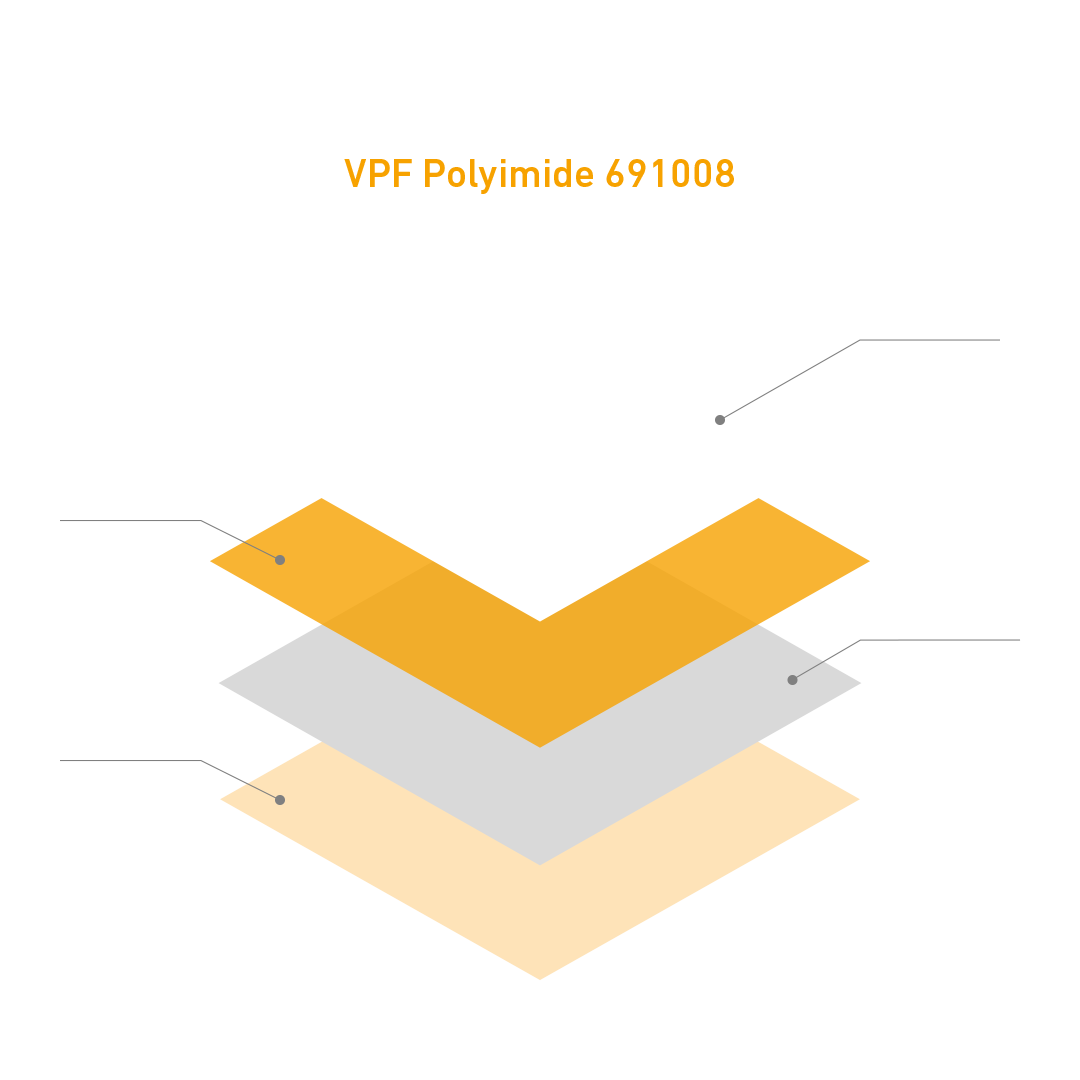

MATERIAL COMPOSITION

Face material

- Yellow polyimide film, surface-coated in white silk matt

- Material thickness: 50 µm

- Very good dimensional stability at high temperatures

Coating

- Optimised for high print quality and contrast

- Excellent thermal transfer printability

- Good scannability for 1D and 2D codes

Adhesive

- VPF adhesive 801

- High-performance acrylate adhesive

- Designed for high-temperature applications

- Temperature resistance: up to 300 °C for short periods

- Very good adhesion to typical printed circuit board surfaces

Liner

- White glassine paper B700-473, 63g

AREAS OF APPLICATION, PROCESS STABILITY,

FURTHER PROCESSING AND DELIVERY FORMATS

Typical areas of application

- Printed circuit board labels

- Marking during wave and reflow soldering processe

- Applications with downstream cleaning processes

- Serial number, barcode and data matrix marking

Process stability

VPF Polyimide 691008 is designed for use in standard printed circuit board manufacturing processes:

- Resistant to high temperatures during wave and reflow soldering

- High adhesive and material stability during thermal peak loads

- Good resistance to standard printed circuit board cleaning processes

Further processing

- Suitable for automatic and manual labelling

- Good running properties in dispensing systems

- Recommended for label manufacturers with high quality and process requirements

Delivery formats

- Available from 200 m²

- Working width: 1,020 mm

POLYIMIDE LABELS FOR CIRCUIT BOARDS

Reliable labelling solutions for printed circuit boards

The labelling of printed circuit boards places the highest demands on materials, adhesives and printability. VPF develops and produces specialised self-adhesive materials that are specifically designed for extreme thermal and chemical stresses in electronics manufacturing – reliable, process-safe and durable.

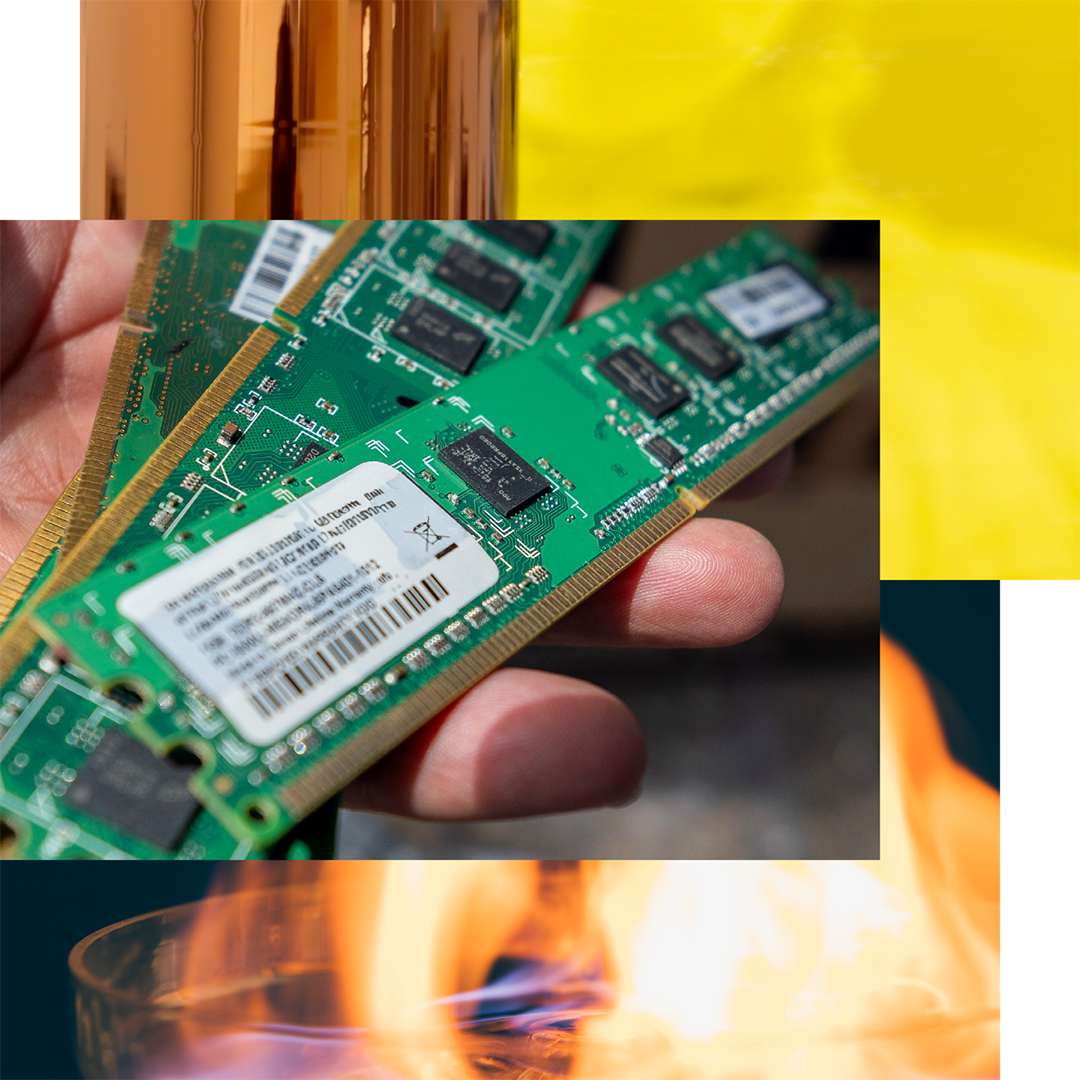

Challenges in the printed circuit board process

In the wave soldering process, printed circuit boards briefly come into contact with liquid solder on their underside. This generates temperatures of up to 280 °C. Depending on the material, board thickness and label position, significantly different temperature profiles can occur on the top side of the board. Adhesive materials must withstand these stresses without deforming, peeling off or losing legibility.

In reflow soldering, components are fixed in place using solder paste, which is melted in an oven. Typically, preheating takes place before peak temperatures of up to 220 °C are reached. In this process, the top side of the circuit board in particular is exposed to high temperatures – here too, maximum material stability is crucial.

Cleaning after soldering

After the soldering process, printed circuit boards are thoroughly cleaned to remove flux residues and prepare the boards for further processing steps. Depending on the manufacturing process, water-based, chemical, high-pressure or ultrasonic cleaning methods are used. VPF’s polyimide self-adhesive materials are designed to remain adhesive-stable and easily readable even under these demanding conditions.

The right material for extreme conditions

Polyimide films are the first choice for circuit board labels at high temperatures. The material is characterised by exceptional heat and chemical resistance and is typically available in thicknesses of 25 µm or 50 µm.

For optimum readability – especially for barcodes and data matrix codes – polyimide films are coated with a high-temperature-resistant white coating. This ensures:

- High contrast

- Excellent printability

- Low reflection during scanning

The system is rounded off by specially developed high-performance adhesives that adhere reliably even under extreme thermal and chemical influences.

Alternative materials such as polyetherimide or other polymer films can be used in less demanding applications, but quickly reach their limits in modern high-temperature processes.

Printing circuit board labels

In practice, thermal transfer printing has become the standard. The key is to combine a suitable adhesive material with a heat-resistant, chemical-resistant ink ribbon to ensure that information remains legible even after soldering and cleaning. The high temperatures involved in the soldering process can also have a positive effect on the durability of the printed image.